Microcement is perfect for those wishing to achieve a completely seamless floor or wall finish that is grout free and aligns with contemporary and modernistic trends. Microcement is a great option for kitchens, living areas, bathrooms and wet rooms because of the ability to completely customise the material in terms of colour, tone and finish. The material also lends itself well to functionality and practicality by offering hygienic and hypoallergenic properties to create a clean and stain free surface environment.

-

THE VERSATILITY OF INFINITE CREATION

THE VERSATILITY OF INFINITE CREATION -

NATTUREA SILKY SMOOTH, ROCK HARD TADELAKT COATING

NATTUREA SILKY SMOOTH, ROCK HARD TADELAKT COATING -

THE TROWELED WATERPROOF MICROCEMENT THAT REDEFINED DECORATIVE COATINGS

THE TROWELED WATERPROOF MICROCEMENT THAT REDEFINED DECORATIVE COATINGS -

THE PERFECT SYSTEM FOR HIGH TRAFFIC SPACES

THE PERFECT SYSTEM FOR HIGH TRAFFIC SPACES

-

THE BEAUTY AND ELEGANCE OF INIMITABLE FINISHES

THE BEAUTY AND ELEGANCE OF INIMITABLE FINISHES -

THE REVOLUTION OF DECORATIVE COATINGS

THE REVOLUTION OF DECORATIVE COATINGS -

THE ESSENCE OF NATURAL WITH OXIDISED FINISHES

THE ESSENCE OF NATURAL WITH OXIDISED FINISHES

-

UNIQUE CREATIONS FOR UNDERWATER SPACES

UNIQUE CREATIONS FOR UNDERWATER SPACES

What is Microcement?

Microcement is a decorative cement based coating with a water based resins, which can be applied thinly (2-3mm) externally and internally to walls and floors in domestic and commercial environments including wood, plasterboard, plywood, marble, tiles, plaster and existing concrete flooring surfaces.

MICROCEMENT BENEFITS

Extremely versatile

Can be applied over any stable interior or exterior surface

100% non-porous

Completely waterproof and mould/bacteria resistant.

Incredible durability

Much stronger than traditional cement and with added elasticity to ensure that it will not crack

Perfect for renovations

Its versatility and minimal thickness (2 to 3mm) means it can be applied to any existing material without the need of demolition or modifications

No joints

Beautifully seamless thanks to its incredible flexibility and strength

Can be used to complement any décor

With a wide range of colours and finishes to choose from, you are only limited by your own imagination

No maintenance required

Does not stain and cleaning is effortless

Eco-Friendly

Every aspect of our products, from their development to their application, utilises eco-technology to ensure no harm to our environment

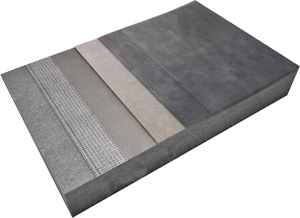

microcement range

STTANDARD & EVOLUTTION

Two-component product line (cement + resin & cement + water ).

It is the traditional microcement and the most used. Its versatility offers a wide variety of finishes and allows its application on an infinite number of surfaces.

Types of Microcement

MICRODECK

Finish coating with natural and homogeneous appearance. It is most suitable to be used on interior floors.

MICROSTONE

Finish coating with stone and uniform effect. It is suitable to create slip-resistant coatings for outdoors.

Efectto Quartz & Efectto PU

Ready to use microcement

It is the ready-to use microcement. Although it is synthetic, it offers a very natural, high quality and inimitable decorative finish. It reduces the effect of water marks while maintaining the texture of the microcement.

NEW!!!

It’s a naturally waterproof microcement. Made from polyurethane and with a two-component composition, it stands out for its low VOC content and superior resistance to abrasion and the dragging of heavy objects. The hardest system on the market.

Natture

Tadelakt microcement with excellent resistance

A silky smooth, rock hard tadelakt coating

Two-component lime-based microcement that stands out for its lower shrinkage and greater chemical and mechanical resistance. Low-thickness continuous coating of extreme hardness for floors and walls.

range of available colours

* The color swatches shown have no contractual value as they are Natural Color System equivalences. These are indicative colors that do not reflect the texture achieved with the Sttandard microcement system. Please note that screen calibration may affect color perception. The final result can only be appreciated after the application is complete, as it depends on the granulometry, the professional's technique, the lighting, and the dimensions of the space.

microcement finishes

IN Natural Effect, super MATT, MATT, SATIN OR GLOSS

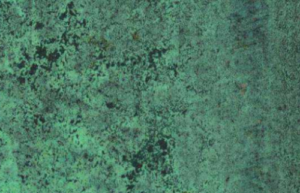

PURE METALLIC

Pure Mettal is the two-component metallic covering that stands out for its ability to create authentic and high-gloss metallic effects. It offers the possibility of obtaining oxidised finishes.

WITH RUST ACTIVATOR

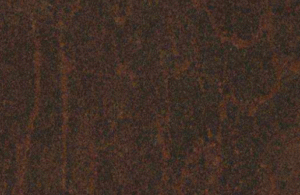

Classic Metallic

Classic Mettal is the ready-to-use range of coatings characterised by its ability to create authentic, high-quality rust effects.

Classic Metal range gives the appearance of rust, when metal activator is applied

with rust activator

Industtrial

Epoxy microcement for interior floors and walls

Industtrial is an exclusive product line of epoxy microcement. A decorative continuous coating especially for interior walls and floors in offices, restaurants and heavy traffic places with the extra hardness provided by epoxy resins.

Industtrial Colours

atlanttic aquaciment

two-component microcement for swimming pools and for spaces in permanent contact with water.

Its innovative formula substantially improves resistance in immersion.

A microcement system with an improved formula to guarantee greater flexibility, hardness, permeability and impermeability available in White (Pigmented) and Natural White (Without pigment)

Microcement creates the perfect balance between hardness and flexibility and at the same time is completely water resistant.

Microcement makes it possible to renovate and decorate old coatings and surfaces, due to the functions of the strong bond and the thin layer

Faq

Despite its lack of thickness, one of this material’s most significant properties is its high resistance and hardness; Microdeck and Microstone can even be used in areas of high traffic.

Several factors influence the resistance and hardness of microcement, such as the support on which it is applied, the type of microcement chosen, as well as the sealant used on the finished microcement.

Microcement can be applied to almost any type of surface: cement mortar, self-levelling compound, hardboard, plywood, marble, tile, plasterboard, over existing plaster and many more. Microcement can also be applied on both vertical and horizontal surfaces in interior and exterior spaces.

The surface must be stable and dry and free of dust or grease.

One of the main properties of microcement is its high adhesion. Thanks to this it is possible to apply microcement on tiles, speeding up the renovation process and avoiding the debris of the original lining. In most cases, we would use fibreglass mesh to strengthen the support of the microcement layers.

Although the aesthetic finish may appear similar, it is not the same.

With microcement one benefits from the following advantages:

- Faster application with microcement

- Microcement has no wait time between pour and polish as polished concrete does (which can save 6 weeks!)

- Microcement requires no large machinery or heavy plant tools required for its application.

- Less time. Lower Cost.

- Microcement is infinitely lighter and thus avoids structural load difficulties.

- It is also 2-3mm deep rather than 50-100mm deep

- Microcement can be used in any room, not just on ground floors and basements.

- Microcement has no joints involved, so no hairline (or larger) cracks appear following the drying process.

- Microcement application possible on both vertical and horizontal surfaces.

Microcement has seamless, crack-proof and waterproof qualities. It is often used in bathrooms, showers, kitchen counters, wet rooms, as external renders, patios and even in swimming pools.

All of the advantages of tiles or external concrete / render with the benefit of no lines, cracks and the endless beautiful appearances to accompany.

Microcement with Highly Decorated comes in several forms some of which naturally have more grit and texture to offer non slip support.

Other types of finer finished Microcement such as the Microfino range are not naturally non slip but can have a non slip element added to the final sealants to ensure they are safer underfoot whilst still sleek and smooth to touch.

A typically install will take 5-6 days.

This consists of the following;

Day 1). Preparation – Epoxy base where required. Fibreglass mesh laid and stuck with water based compound

Day 2). First Coat of Microbase trowelled on.

Day 3). First Coat of Microbase sanded down with electric hand held sanders. Second Coat of Microbase trowelled on.

Day 4). Second Coat of Microbase sanded down with electric hand held sanders. First Coat of final Microcement Compound trowelled on (fine, deck, stone)

Day 5). First Coat of final Microcement Compound (fine, deck, stone) sanded down. Second coat of final Microcement compound trowelled on

Day 6). Second coat of final Microcement compound sanded down. Final 4 coats of presealer and sealer applied. This gives floor / walls ultimate protection, non-slip elements where required and the final desired finish (matte, satin or gloss)

To ensure the long and durable life of our microcements, we recommend the use of water and neutral soaps.

The care of microcement is similar to that of natural wood parquet. We advise to avoid permanent wetness, or prolonged contact with moisture. The surfaces should also be kept free of stones or grit which can scratch the coating. Avoid any blows and rubbing with hard objects.

Although microcement offers a high resistance to chemicals, cleaning should be done with neutral soaps, never with aggressive or descaling products. Additionally, avoid products such as chlorine, bleach, ammonia, soaps and detergents in general, as they can damage the protective film.

Microcement Training Course

Who is the training for?

Contractors, who would like to learn about microcement technology and people related to the construction industry, who already carry out, for example, resin floors or finishing works. We are also happy to train architects and designers who want to expand their knowledge of the technical aspects of microcement in order to be able to better advise their clients.

What will you learn during the training?

You will learn different techniques that exist depending on the type of decorative coating and the surface or substrate to be coated. We will advise you on the preparation, application, sealing and maintenance of microcement and other decorative finishes.

Free lunch and drinks provided.

Please email us for more information on dates and prices.